SHYAM INSTRUMENTS & CALIBRATION SERVICES

NABL Accredited Laboratory

Give us your valuable Feedback

For Specific Requirenments

General Electrical Test

Power Quality Measurement

With the increased sophistication of electrical and electronic equipment, and new micro generation systems being added to the grid, there is now more than ever attention being paid to the quality of supply. Power quality surveys on electrical noise, lamp flicker, load balancing, power factor correction and motor in-rush studies can all be carried out with Megger power quality analysers.

Power quality analysis system MPQ1000

■ Configuration verification which identifies and notifies you if the product has been connected incorrectly.

■ On-board data analysis which can compare results against canned or custom standards. Create your own templates for internal your company standards.

■ SD Card Support, USB Card Support, USB Communications as well as Ethernet connections, making it versatile.

MPQ2000

■ Weather proof to NEMA 4 standard for use in any environment

■ Auto CT identifies the current that the instrument is connected to and it’s range

■ Configuration verification which highlights if the product has been connected incorrectly

■ On-board data analysis which can compare results against compliance standards, including setting templates for internal company standards

Impedance meter NIM1000

Earth or Ground Testing

One of the most important considerations in an electrical system is the resistance of the earth for reliable operation and safety. Whether you are doing a ground resistivity survey to plan the location of a substation or testing an earth electrode Megger has an earth tester suitable for the job. Megger has more than 50 years’ experience of designing and building earth resistance testers. The latest generation is CATIV rated, and have tough moulded cases. Variable test frequency keeps noise down, reliability up.

Advanced Earth Tester DET2/3

Earth Test Kit

Earth ground testers DET3 and DET4

■ Extra large selector switch

■ Extra large, clear display for easier operation in outdoor conditions

■ Simple one button operation

■ Battery powered with a bar graph that updates battery strength

Earth resistance clamp testers DET14C and DET24C

■ Low maintenance flat jaw interface

■ Measures ground resistance from 0.05 Ω to 1500 Ω

■ Measures true RMS ground leakage current from 0.5 mA rms to 35 A rms

■ Automatically self calibrates

Professional earth test kit

■ 4 wires on easy-wind reels make it quick to get testing and quick to pack away again

■ 1 croc clip test wire

■ Fibre-glass measuring tape to assist accuracy depth

■ Auger style spikes make it easy to deploy and to check

Battery Testing

With the increasing dependency of back-up systems on battery strings, and the escalating cost of replacing batteries, instrumentation and software systems that can measure, trend and manage the life-cycle of cells is a cost effective option. There are two methodologies for testing batteries; the first, impedance testing is an on line test and can be performed

frequently to identify individual weak cells before they fail. The second, battery discharge test is, normally, an off-line test and tests the actual output of the whole battery under load conditions. This will show what will actually happen if the battery is required to take the load. Most battery systems are floating and have earth leakage monitors and trips if there is an earth fault. The Battery Ground Fault Tracer allows you to trace a faulty circuit easily in a complex floating system.

Battery impedance test equipment BITE3

Battery impedance tester for up to 7000 Ah cells BITE2P

DC earth fault locator Geolux GL660-1

Battery ground fault tracer BGFT

Battery Load Units TORKEL910, TORKEL930 and TORKEL950

Battery voltage monitoring BVM series

Digital hydrometer

Battery extra load TXL

Battery testing software TORKEL Viewer

Rotating Machine Testing

Baker Instruments’ motor test equipment are the industry-leading suite of products for detecting weaknesses and faults in the insulation systems of electric motors, generators and coils. Employing both low-voltage and high-voltage tests – such as Baker’s signature surge test – these essential troubleshooting and predictive maintenance tools allow maintenance professionals to assess any need to maintain or replace specific motors and generators that support their business. Equally at home in the motor repair shop or on a plant floor, these testers ensure that the electrical condition of your rotating machinery is understood.

Static Motor Analyzer Baker AWA-IV

Static Motor Analyzer Baker DX

Multifunctional Tester MTR105

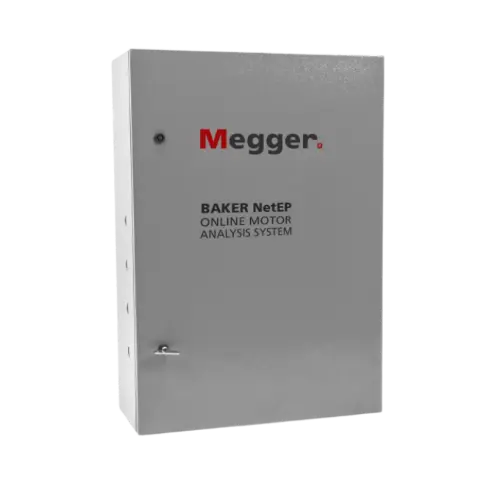

On-Line Motor Analysis System Baker NetEP

Dynamic Motor Analyzer Baker EXP4000

Power Packs Baker PPX power packs

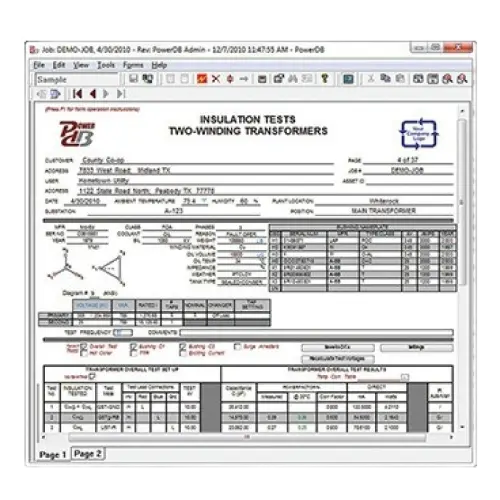

Test Data Management Software

PowerDB

Low Voltage Testing

Electrical contractors throughout the world depend on hand-held test equipment to ensure installations are safe and function correctly. Count on Megger to produce tough machines that are designed to surpass the requirements of wiring regulations.

Thermal Camera TC3231

Earth loop impedance testers LT300

LTW425

LTW300 Series

Residual current device testers RCDT300 series

Multimeters AVO800 series

AVO210

Clampmeters DCM series

DCM305E

Isolation test kits TPT420 and MPU690

Portable appliances testing PAT100 series

Portable appliances testing PAT300 series

Portable appliances testing PAT400 series

Multifunction installation tester MFT series

Combined Insulation & Continuity Testers

Pocket sized insulation and continuity tester MIT200 series

Insulation resistance and continuity testers for industrial maintenance MIT400/2 Series

Insulation resistance and continuity testers for electricians MIT300 series

Insulation resistance and continuity testers for telecommunications MIT480/2 Series